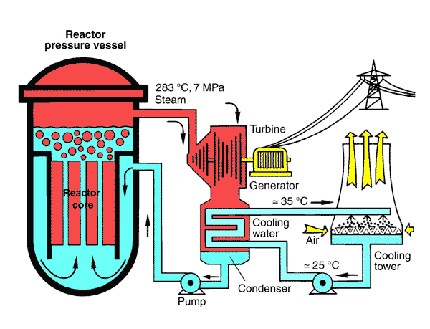

Nuclear reactorSee 'reactor'. with water as a coolantAny substance used to remove the heat in a nuclear reactor. ... and as a moderatorMaterial used to "decelerate" fast neutrons to low energies,..., boiling in the corePart of the nuclear reactor where the fission chain reaction.... The resulting steam is generally used directly to drive a turbine. Example: Nuclear Power PlantThermal power plant, primarily used for electricity generati... Gundremmingen, Unit C, 1,344 MWeMegawatt electric; electric output of a power plant in megaw.... The fuelSee 'nuclear fuel'. elements containing the uraniumNatural radioactive element with the atomic number 92. The n... dioxide are located in the pressure vesselThick-walled cylindrical steel vessel enclosing the reactor ..., two thirds of which are filled with water. The water flows through the corePart of the nuclear reactor where the fission chain reaction... from bottom to top and removes the heat developed in the fuelSee 'nuclear fuel'. elements. Part of the water evaporates. Following steam-water separation in the upper part of the pressure vesselThick-walled cylindrical steel vessel enclosing the reactor ..., the saturated steamSee wet steam. at a temperature of about 290 °C and a pressure of approx. 70 bar (7 MPa) is fed to the turbine. This amounts to up to 7,500 t steam per hour. The turbine is coupled to a three-phase generator. The steam exiting the turbine is liquefied in the condenser. For this purpose about 160,000 m3 cooling water per hour is required and is taken from the cooling towerTower-like concrete construction for closed-circuit cooling.... circuit. The feed water is heated to a temperature of about 215°C by means of a heating system and refed into the reactorSystem used to initiate, maintain and control a fission chai.... The control rods containing the neutron-absorbing material are inserted in the corePart of the nuclear reactor where the fission chain reaction... from below by means of an electromotor (normal drive) or hydraulically (tripFast shutdown of a nuclear reactor, generally by fast insert...). The piping leads out of the containmentGastight case around a reactor and the circuit and auxiliary... into the engine house. A number of safety devices are installed to achieve immediate isolation of the reactorSystem used to initiate, maintain and control a fission chai... from the engine house in case of a malfunction.

Diagram boiling water reactor