Nuclear technology is a major contributor to industrial development and it is present in many aspects of our daily lives.

Figure 1: Silicon is irradiated with neutrons, resulting in transmutation into a stable 31P isotope.2

Computers, wind turbines, photovoltaic panels, high-speed trains, hybrid cars: all these applications use doped silicon in their electronic circuits. Silicon is naturally present in the soil, but pure silicon is an insulator that cannot pass any electrical current because of the absence of free electrons.

Silicon becomes an ideal semiconductor in electronics thanks to the addition of impurities. This process, called “doping”, creates free electrons. The doping of silicon crystals is done in research reactors such as BR2, operated by SCK • CEN (Centre for the Study of nuclear energy) in Mol.

Lithium-ion batteries are now used in many high-energy portable devices: Mobile phones, flashlights, digital cameras and laptops are just a few examples. They are also used in electric cars as energy storage systems or are considered intermediate storage for renewable energies.

In order to increase their lifespan or speed up the loading process, further research is carried out on batteries using neutron-based investigation methods. Imaging techniques based on neutron beams are rapidly developing and have become versatile non-destructive analyzing tools in many research fields. Due to their intrinsic properties, neutrons differ strongly from electrons, protons or X-rays in terms of their interaction with matter: they penetrate deeply into most common metallic materials while they have a high sensitivity to light elements such as hydrogen, hydrogenous substances, or lithium. This makes neutrons perfectly suited probes for research on materials that are used for energy storage and conversion, e.g., batteries, hydrogen storage, fuel cells, etc. 3

A potential future energy source is hydrogen. It can be generated using renewable energies and converted into electrical energy emission-free in fuel cells at a later stage.

Neutron imaging can help us to understand many fundamental questions related to hydrogen fuel. For example, where does the hydrogen migrate at the various stages of storage? Which materials store the most? What temperature and pressure conditions are optimum for their operation, and what are the limits?

Most cleaners for paint or adhesive residues in the construction and DIY sectors consist predominantly of volatile organic solvents that release components that are harmful to the environment and health. Thanks to the research neutron source at the Technical University Munich, a replacement was found and tested that allows these harmful parts to be significantly reduced or dispensed with altogether. For the first time, a paint solvent was created, which removes heavy soluble residues of paint and varnish as well as soot, tar and adhesives with a small amount of surfactant and without the addition of organic solvents.

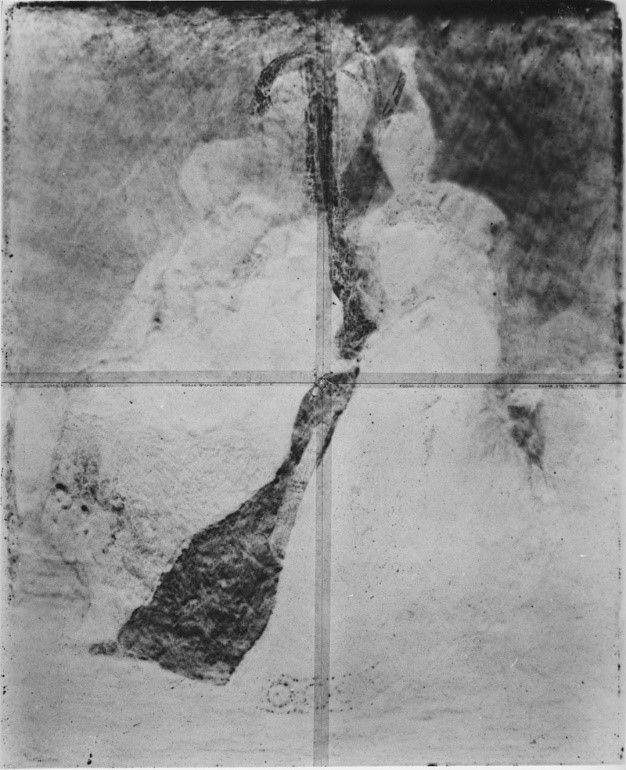

Figure 3: Rembrandt Harmensz van Rijn, Minerva, 5. Neutron autoradiography shows a different painting underneath (photo: C. Laurenze-Landsberg)

With neutrons and photons, historical objects can be examined very gently and non-destructively (Figure 3 and 4). More and more art historians and archaeologists are turning therefore to nuclear research institutes to study historical pieces in their collections, and information can be revealed by neutron scan.

For example, for a long time it was not clear whether the painting “Armida abducts the euthanised Rinaldo” is an original by the French painter Nicolas Poussin (1594 – 1665). Studies at the Helmholtz Institute Berlin have shown that pre-sketched trees of the same species and identical color pigments were painted over, for art historians a sure sign that this is an original. Using neutron imaging has also shown different paintings beneath existing ones (Figure 2 and 3)

Sensitive, accurate and reliable control systems are essential to industry. Nucleonicgauges – instruments that use a radioisotope source to measure materials and products – can improve product quality, optimise industrial processes and save energy and materials. They are extremely sensitive, and often succeed where other methods fail.

Nucleonic gauges are ideal for arduous or dangerous industrial environments, including high-temperature and high-pressure situations. They are also non-invasive – no physical contact is required between the sensor and the material – thus quality checks can be performed on-line during production. Sizeable financial benefits can be realised from the reduction of scrap and waste and the assurance of high quality products that retain customer loyalty.

The metal-coating industry uses nucleonic gauges to ensure optimum coating thicknesses. Moisture gauges are essential in industries involving construction materials, glass, mineral processing, chemicals and food. Radioisotope gauges, used to measure mass per unit of area – often at high speeds – are indispensable in manufacturing aluminium foil, paper and steel plate.

It is essential to test some materials, products, engineering structures or buildings without altering their properties or affecting their usefulness. Non-destructive testing (NDT) comes in many forms, one of the most popular being radiography, which uses a radioisotope or X-ray source. NDT radiography is used extensively in the petroleum, chemical and nuclear industries, as well as on assembly lines to test consumer goods. Light alloy castings, such as car wheels, receive a quality check of this type before leaving the factory. Pipelines, too, are prime NDT candidates – both during installation and maintenance – to ensure that welds remain intact.

In NDT radiography, gamma rays from a sealed source or X-rays are directed through the object, and the results shown on film or other media. Imperfections are indicated as the density changes – just as a body X-ray reveals broken bones. A recent development is real-time radiography, where faults can be evaluated on a computer screen for assembly-line inspections and troubleshooting.

References

1 SCK CEN (2019) – Neutron Doped Silicon Production, Accessed 19/08/19 at: <https://science.sckcen.be/en/Services/Irradiations/Silicon>

2 Petry, Winfried. (2015) – Neutrons for Industry. EPJ Web of Conferences, 104, 01001. DOI: 10.1051/epjconf/201510401001

3 Kardjilov, Nickolay., Manke, Ingo., Woracek, Robin., Hilger, Andre. (2018). Advances in Neutron Imaging. Materials Today, 03, 001. DOI: 10.1016/j.mattod.2018.03.001

Figure 2: Rembrandt Harmensz van Rijn, Minerva, c. 1631, oak, 60.5 x 49 cm, picture gallery, Staatliche Museen zu Berlin (photo: V.H. Schneider)