Framatome Opens Spent Resin Treatment R&D Project in Karlstein

Framatome (ENS Corporate Member) has successfully built and commissioned a semi-industrial scale Spent Resin Liquefaction facility at its site in Karlstein-am-Main, Germany.

The Framatome site in Karlstein, near the Frankfurt area, is the most suitable location for the installation of the semi-industrial scale facility. The engineers from the waste management department work on the site and a building housing other technologies, such as solidification and with all the necessary connections and media, is available.

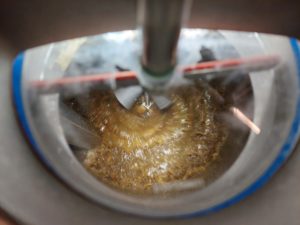

View into the reactor module in which the resins are treated. Ph. Framatome

The new Spent Resin Treatment system liquefies bead resins using a wet oxidation process developed by Framatome. At the heart of the process is the reactor module in which the resins are treated. A second bigger module houses the different measurement and process control equipment. Along with modules for dosing and off-gas treatment, the four parts form the Spent Resin Treatment facility.

Through this Resin Liquefaction project, Framatome will further investigate process parameters with special emphasis on safety and process stability. A second work package will use suitable recipes to embed the resulting effluent from the resin liquefaction process in different matrices, such as cement or geopolymers. The cementation laboratory in Karlstein and available mixing technology will be used to develop the recipes.

The Spent Resin Liquefaction project is co-funded by the German Federal Ministry of Education and Research (BMBF) as part of the FORKA project.